AutoLink Series Interface Conveyors - Featured at PACK EXPO

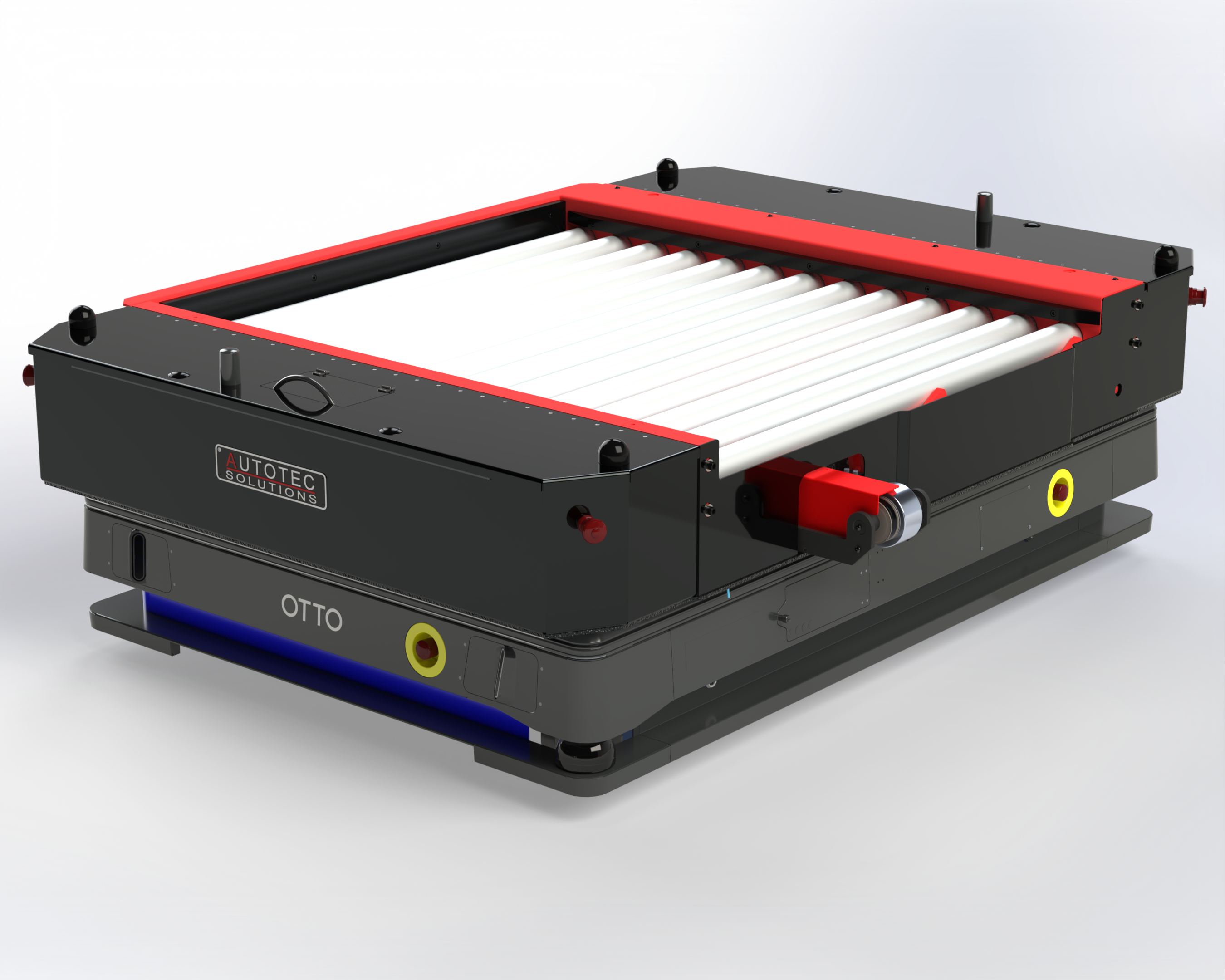

Autotec AMR Interface Conveyor

The AutoLink 1500 CDLR (Chain Driven Live Roller) Module is a top-of-the-line, automated material handling system designed by Autotec Solutions specifically for integration with the OTTO 1500 autonomous mobile robot (AMR).

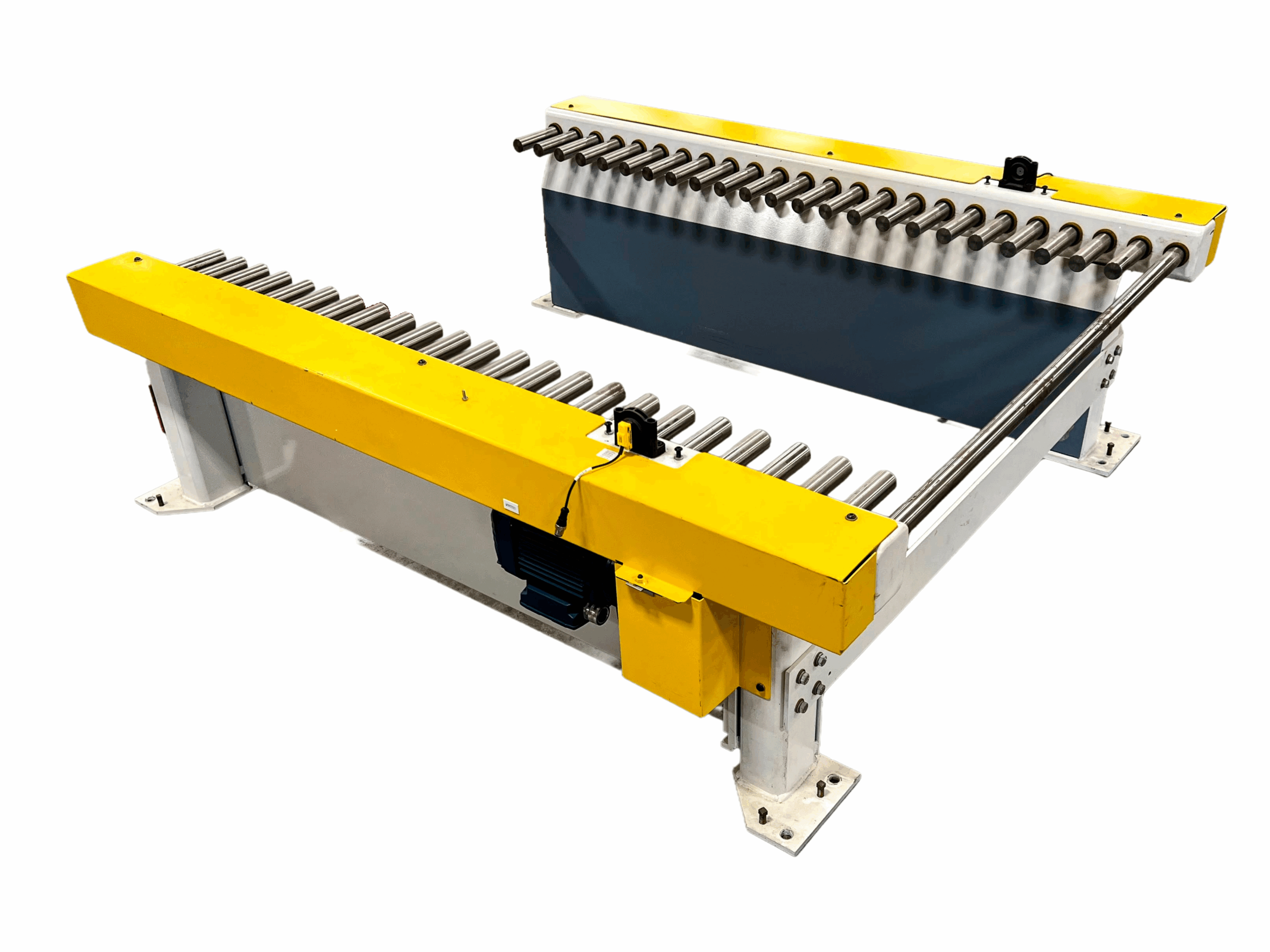

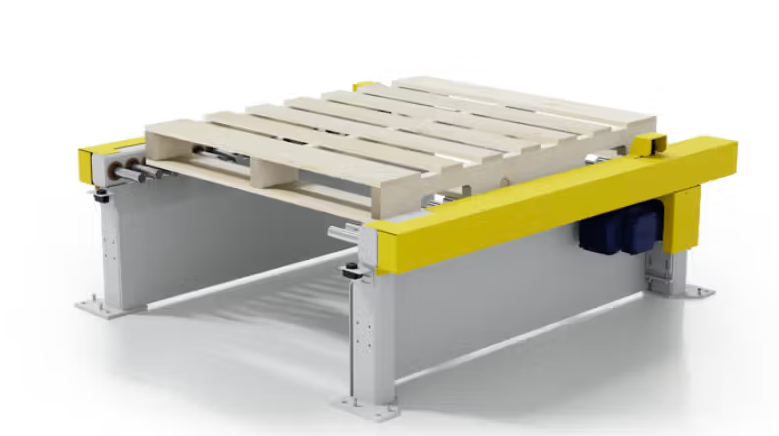

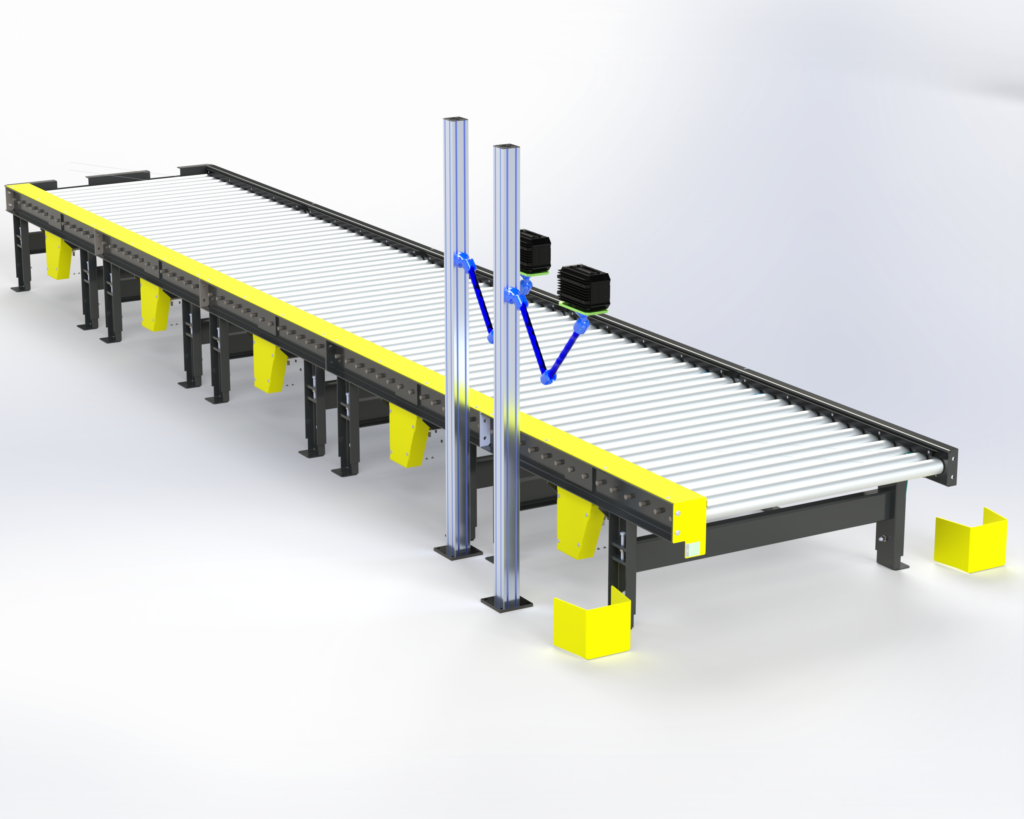

AMR Stubshaft Conveyor

Autotec's Stubshaft Conveyor is a versatile pallet-handling solution built to excel in dynamic material handling environments. Engineered to bridge the gap between fixed automation systems and autonomous mobile robot (AMR) workflows, this conveyor can also operate as a standalone system, adding unmatched flexibility to your operations.

With a robust design capable of supporting up to 3,000 lbs in its standard configuration, the Stubshaft Conveyor ensures reliable performance under heavy loads. It is not only structurally durable but also optimized for seamless workflow integration, featuring integrated pallet presence sensing. This advanced sensing capability enhances accuracy and efficiency, enabling smooth and consistent handling across operations.

Designed with durability and reliability in mind, the Stubshaft Conveyor is an ideal solution for industries needing a flexible yet sturdy pallet-handling conveyor that can adapt to the demands of modern automated facilities.

Discover Autotec Solutions

At Autotec Solutions, our dedication to innovation, excellence, and customer satisfaction drives us to provide unparalleled solutions across multiple industries. With a legacy that spans over five decades, we have consistently evolved, integrating the latest technologies with our engineering expertise to deliver solutions that not only meet but exceed the expectations of our clients. Here’s how we stand out:

Tailored Precision

We specialize in engineering custom automation systems that are meticulously tailored to your precise operational needs. Our approach ensures seamless integration and optimal performance, empowering your business to operate more efficiently and effectively. From conceptualization to the final implementation, every solution we deliver is crafted to address the unique challenges and demands of your operations. With Autotec Solutions, precision is not just a goal; it’s a guarantee.

Turnkey Solutions

Autotec Solutions is your single-source provider for comprehensive turnkey automation solutions. Our team guides you from the initial concept through to commissioning, ensuring a smooth, hassle-free process. With our extensive experience and expertise, we handle all aspects of your project, significantly reducing complexity and enhancing productivity. By entrusting us with your needs, you can focus on what you do best, knowing that your project is in capable hands.

Your Partner in Innovation

We at Autotec Solutions are more than just a vendor; we are a partner in your quest for excellence and growth. Leveraging cutting-edge robotic vision, industrial automation, and safety technologies alongside our in-depth industry expertise, we aim to provide solutions that are not only advanced but also sustainable and adaptable to future demands.

Collaborating with Autotec Solutions opens the door to innovation, quality, and exceptional outcomes for your business. Reach out to us today, and let's embark on a journey to redefine what's possible.

Start Your Automation Journey

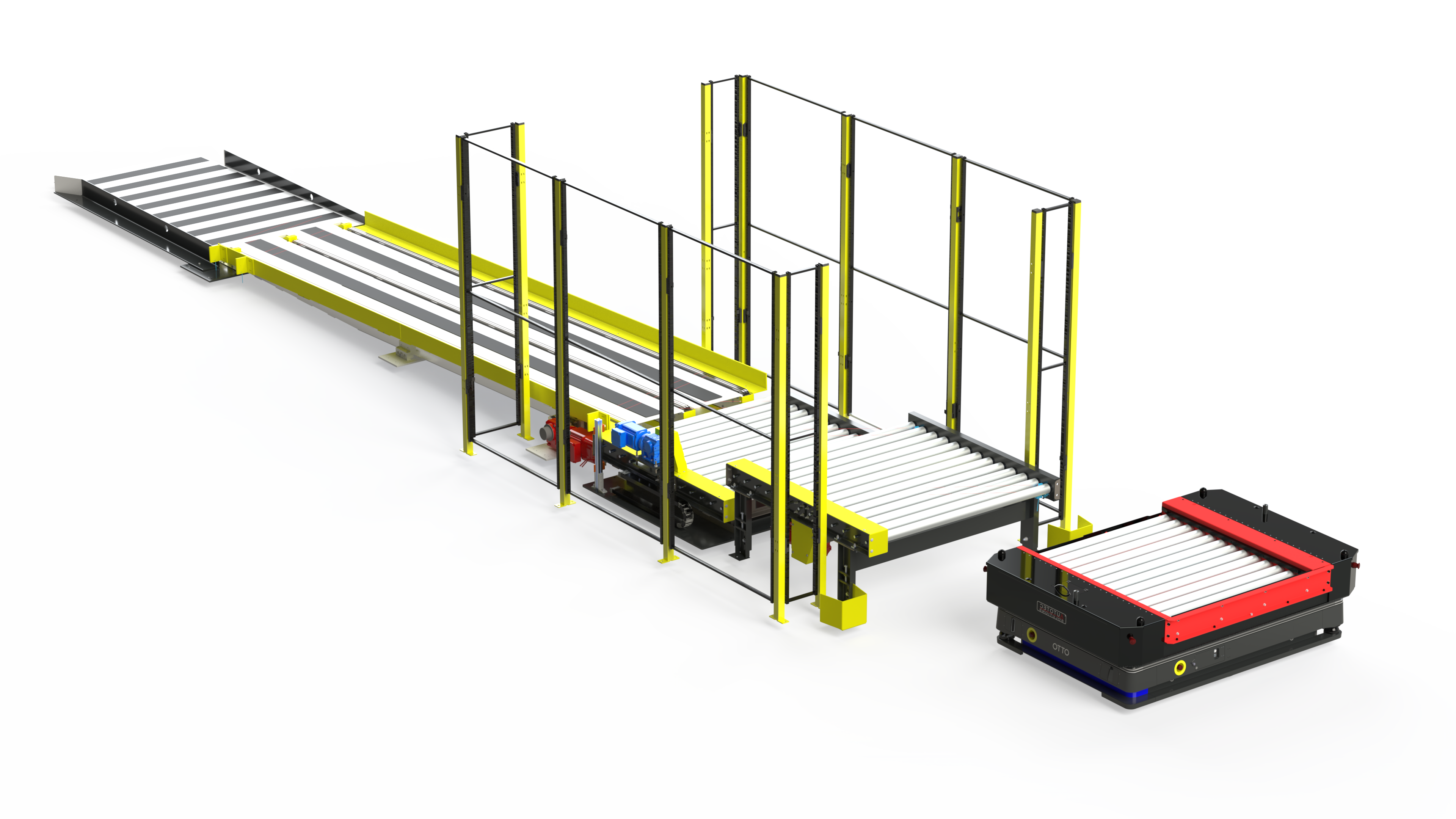

AutoLink Series Interface Conveyors

The Stubby Butler - AMR Interface Conveyor

The AutoLink 1500 CDLR (Chain Driven Live Roller) Module is a top-of-the-line, automated material handling system designed by Autotec Solutions specifically for integration with the OTTO 1500 autonomous mobile robot (AMR).

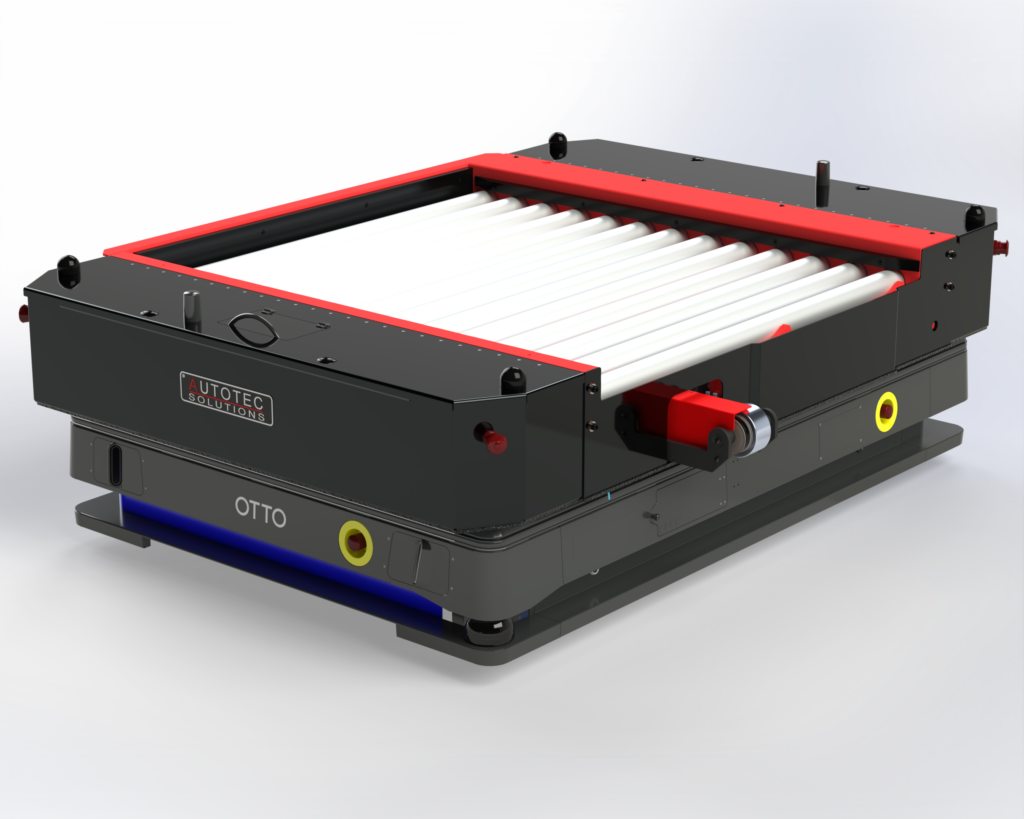

AMR Powered Conveyor

The AutoMove 1500 Top Module, crafted by Autotec Solutions, is an automated material handling system that seamlessly integrates with the OTTO 1500 autonomous mobile robot (AMR). It enhances its functionality with the optional AutoLink PTO, enabling efficient powered transfers to non-powered passive conveyors like the AutoLink 1500 Pickup & Drop-off Conveyor Stand. Additionally, this versatile top module possesses the capability to interact with conventional powered conveyors.

AutoMove with AutoLink PTO

The AutoLink 1500 CDLR (Chain Driven Live Roller) Module is a top-of-the-line, automated material handling system designed by Autotec Solutions specifically for integration with the OTTO 1500 autonomous mobile robot (AMR).

AMR Powered Conveyor

The AutoMove 1500 Top Module, crafted by Autotec Solutions, is an automated material handling system that seamlessly integrates with the OTTO 1500 autonomous mobile robot (AMR). It enhances its functionality with the optional AutoLink PTO, enabling efficient powered transfers to non-powered passive conveyors like the AutoLink 1500 Pickup & Drop-off Conveyor Stand. Additionally, this versatile top module possesses the capability to interact with conventional powered conveyors.

AutoLink 1500 PD1

The AutoLink 1500 CDLR (Chain Driven Live Roller) Module is a top-of-the-line, automated material handling system designed by Autotec Solutions specifically for integration with the OTTO 1500 autonomous mobile robot (AMR).

AMR Powered Conveyor

The AutoLink 1500 Pickup & Drop-off Conveyor Stand, developed by Autotec Solutions, is a non-powered conveyor engineered for direct integration with autonomous mobile robots (AMRs) equipped with the AutoLink PTO. This system is designed without wiring to facilitate ease of installation and maintenance in industrial applications, ensuring compatibility with AMR systems for streamlined logistics and material handling processes.

AutoLink Custom Conveyors

AutoLink Custom Conveyors by Autotec Solutions are expertly engineered to meet the unique requirements of modern material handling processes. These conveyors are designed with flexibility in mind, ensuring seamless integration with autonomous mobile robots (AMRs) like the OTTO 1500. Whether tailored to specific operational needs or built to accommodate unconventional workflows, AutoLink Custom Conveyors provide robust and reliable performance in industrial applications. From powered transfers with PTO technology to non-powered passive systems, each custom solution enhances efficiency, reduces manual intervention, and optimizes logistics to meet the challenges of high-demand environments.

Standard & Custom AMR Powered Conveyors

Autotec Solutions offers Standard and Custom AMR Powered Conveyors to streamline logistics across warehouses, manufacturing facilities, and distribution centers. Designed for compatibility with AMRs such as the OTTO 1500, these systems provide efficient material transport and handling with options for passive and powered conveyor configurations. The integration of PTO-enabled modules ensures smooth interaction between powered and non-powered conveyors, maximizing operational flexibility. With meticulous attention to system customization, these conveyors can adapt to unique workflows, enhance throughput, and elevate automation for facilities of any size.

ideal use cases

Warehouse Operations

Streamline the movement and storage of various goods with safe and efficient pallet handling.Manufacturing Facilities

Facilitate the seamless transfer of materials between different stages of production.Distribution Centers

Enhance loading and unloading efficiency, crucial for timely distribution operations.Large-Scale Retailers

Operates without needing the count of boxes per pallet layer, adding to its intuitive design.AMR Conveyance Systems

Versatile Pallet Handling

Optional Power Take Off

Software Integration

High Load Capacity

additional AutoMove Series Conveyors

AutoMove with AutoLink PTO

The AutoLink 1500 CDLR (Chain Driven Live Roller) Module is a top-of-the-line, automated material handling system designed by Autotec Solutions specifically for integration with the OTTO 1500 autonomous mobile robot (AMR).

AMR Powered Conveyor

The AutoMove 1500 Top Module, crafted by Autotec Solutions, is an automated material handling system that seamlessly integrates with the OTTO 1500 autonomous mobile robot (AMR). It enhances its functionality with the optional AutoLink PTO, enabling efficient powered transfers to non-powered passive conveyors like the AutoLink 1500 Pickup & Drop-off Conveyor Stand. Additionally, this versatile top module possesses the capability to interact with conventional powered conveyors.

AutoLink 1500 PD1

The AutoLink 1500 CDLR (Chain Driven Live Roller) Module is a top-of-the-line, automated material handling system designed by Autotec Solutions specifically for integration with the OTTO 1500 autonomous mobile robot (AMR).

AMR Powered Conveyor

The AutoLink 1500 Pickup & Drop-off Conveyor Stand, developed by Autotec Solutions, is a non-powered conveyor engineered for direct integration with autonomous mobile robots (AMRs) equipped with the AutoLink PTO. This system is designed without wiring to facilitate ease of installation and maintenance in industrial applications, ensuring compatibility with AMR systems for streamlined logistics and material handling processes.

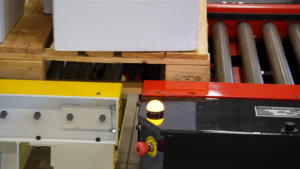

On The Fly System Integrations

Numerous integration options exist for incorporating the random case palletizer into various warehousing and manufacturing systems. We’ve established several standard system integrations, including rotary arm stretch wrappers, conveyors that interface with Autonomous Mobile Robots (AMR), and robots mounted on rails.

Rotary Arm Stretch Wrapper

The Rotary Arm Stretch Wrapper is an automated system with an infeed, wrapper zone, and outfeed conveyor. It wraps stationary loads with a 20-inch film, featuring a 200% standard pre-stretch for 60 to 100 gauge films. Safety is ensured with fencing and a light curtain, capable of wrapping loads up to 87 inches high. The machine offers adjustable wrap patterns through the HMI and includes a pop-up feature for thorough wrapping.

FLEET MANAGEMENT EXPERIENCE

Automate material handling at enterprise-scale with the world’s most powerful Autonomous Mobile Robot (AMR) fleet management software.

As a system integrator, Autotec Solutions has expertise in deploying OTTO Fleet Manager software for various clients. Our experience ensures seamless integration with existing infrastructure, providing a symbiotic enhancement to efficiency and intelligence in automated material transport systems.

Robots On Rails

The optional Robotic Transfer Unit elevates productivity to new levels. This state-of-the-art addition, functioning as a robot on rails, incorporates robot-mounted vision technology. It effectively increases the number of pick and build locations, thereby enhancing overall operational efficiency. By capitalizing on this feature, businesses can significantly maximize their spatial utilization and throughput, making it a worthy investment for high-volume operations.

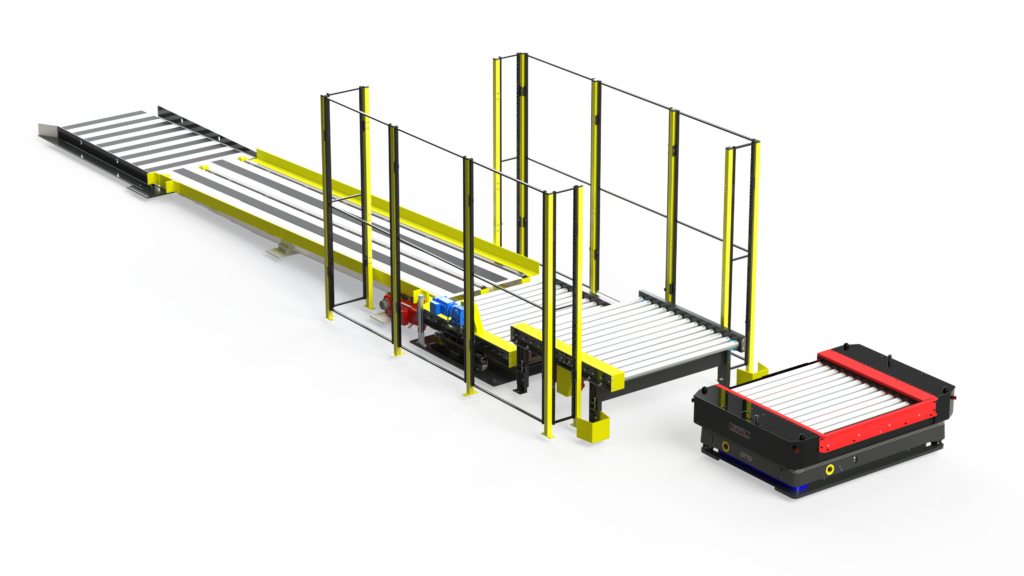

AutoMove with AutoLink PTO Integration

The AutoLink 1500 CDLR Top Module is a top-of-the-line, automated material handling system designed by Autotec Solutions specifically for integration with the OTTO 1500 autonomous mobile robot (AMR). It revolutionizes the way logistics and warehouse operations handle various pallet types and sizes, ensuring increased adaptability, safety, and space optimization.

Dock

Instantly adapting to mixed box sizes and orientations, enabling seamless, uninterrupted packing and stacking in real-time.

Engage

Enabling precise, real-time object recognition and positioning for efficient automation processes.

Transfer

Simultaneously constructs pallet stacks at multiple locations, optimizing throughput and workspace utilization with mixed case capabilities.

Design Your System

Please get in touch with us to discuss your AMR needs and talk about your full system requirements.