AMR Conveyance Systems

Versatile Pallet Handling

Optional Power Take Off

Software Integration

High Load Capacity

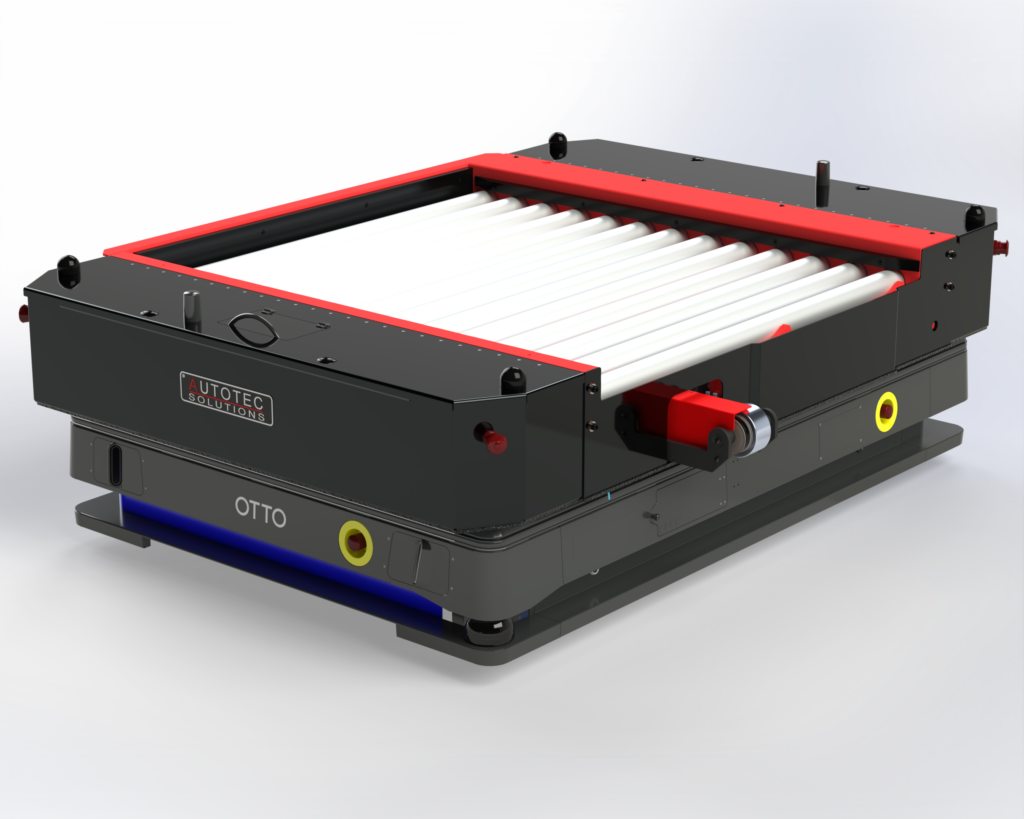

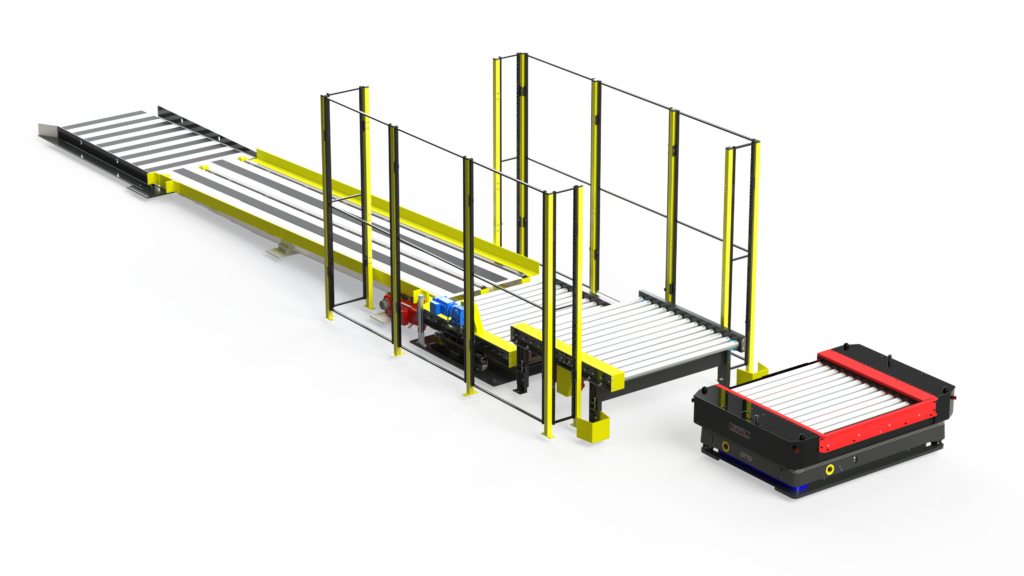

AutoMove with AutoLink PTO Integration

The AutoLink 1500 CDLR Top Module is a top-of-the-line, automated material handling system designed by Autotec Solutions specifically for integration with the OTTO 1500 autonomous mobile robot (AMR). It revolutionizes the way logistics and warehouse operations handle various pallet types and sizes, ensuring increased adaptability, safety, and space optimization.

Dock

Instantly adapting to mixed box sizes and orientations, enabling seamless, uninterrupted packing and stacking in real-time.

Engage

Enabling precise, real-time object recognition and positioning for efficient automation processes.

Transfer

Simultaneously constructs pallet stacks at multiple locations, optimizing throughput and workspace utilization with mixed case capabilities.

Design Your System

Please get in touch with us to discuss your AMR needs and talk about your full system requirements.

AutoLink Series Conveyors

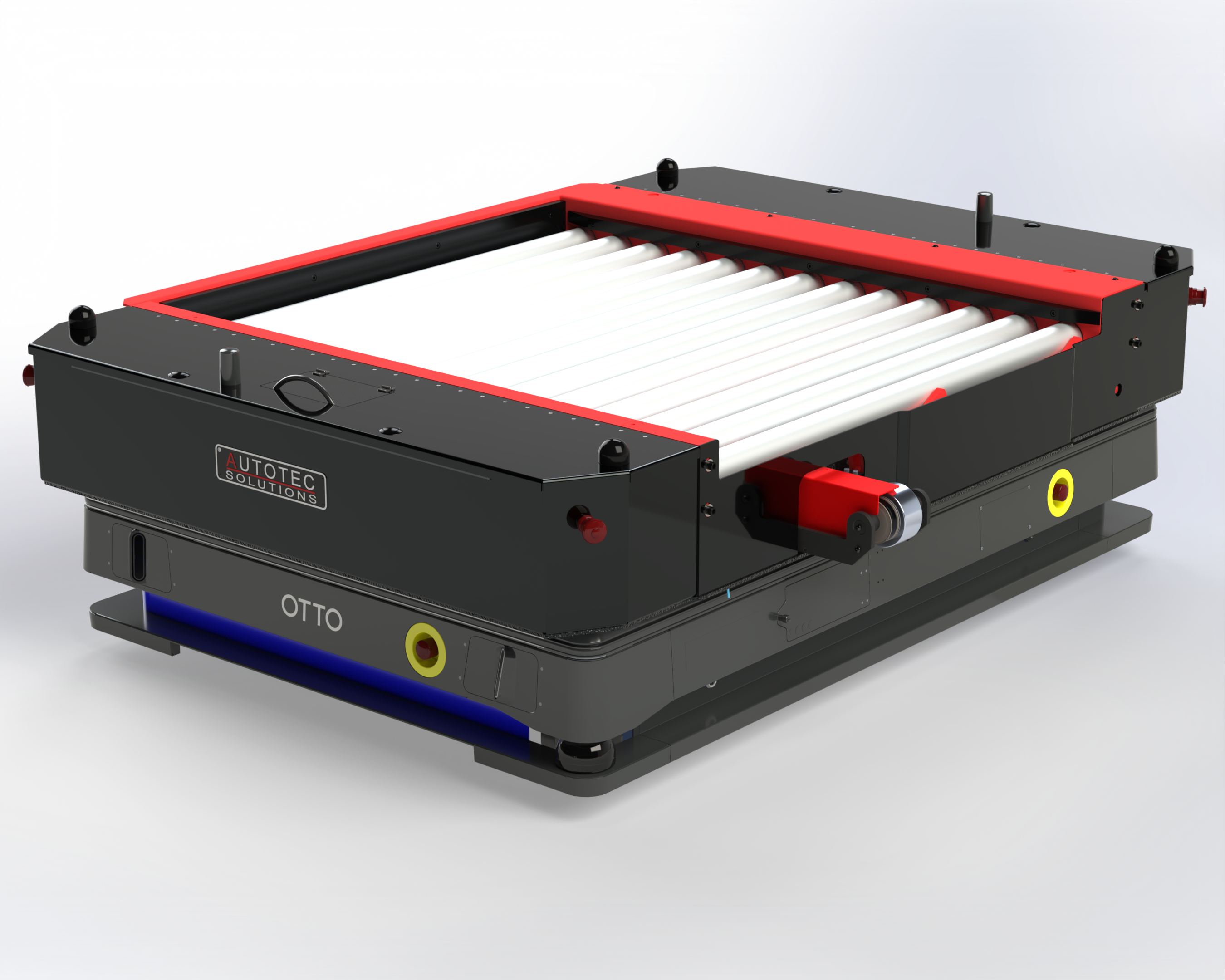

AutoMove with AutoLink PTO

The AutoLink 1500 CDLR (Chain Driven Live Roller) Module is a top-of-the-line, automated material handling system designed by Autotec Solutions specifically for integration with the OTTO 1500 autonomous mobile robot (AMR).

AMR Powered Conveyor

The AutoMove 1500 Top Module, crafted by Autotec Solutions, is an automated material handling system that seamlessly integrates with the OTTO 1500 autonomous mobile robot (AMR). It enhances its functionality with the optional AutoLink PTO, enabling efficient powered transfers to non-powered passive conveyors like the AutoLink 1500 Pickup & Drop-off Conveyor Stand. Additionally, this versatile top module possesses the capability to interact with conventional powered conveyors.

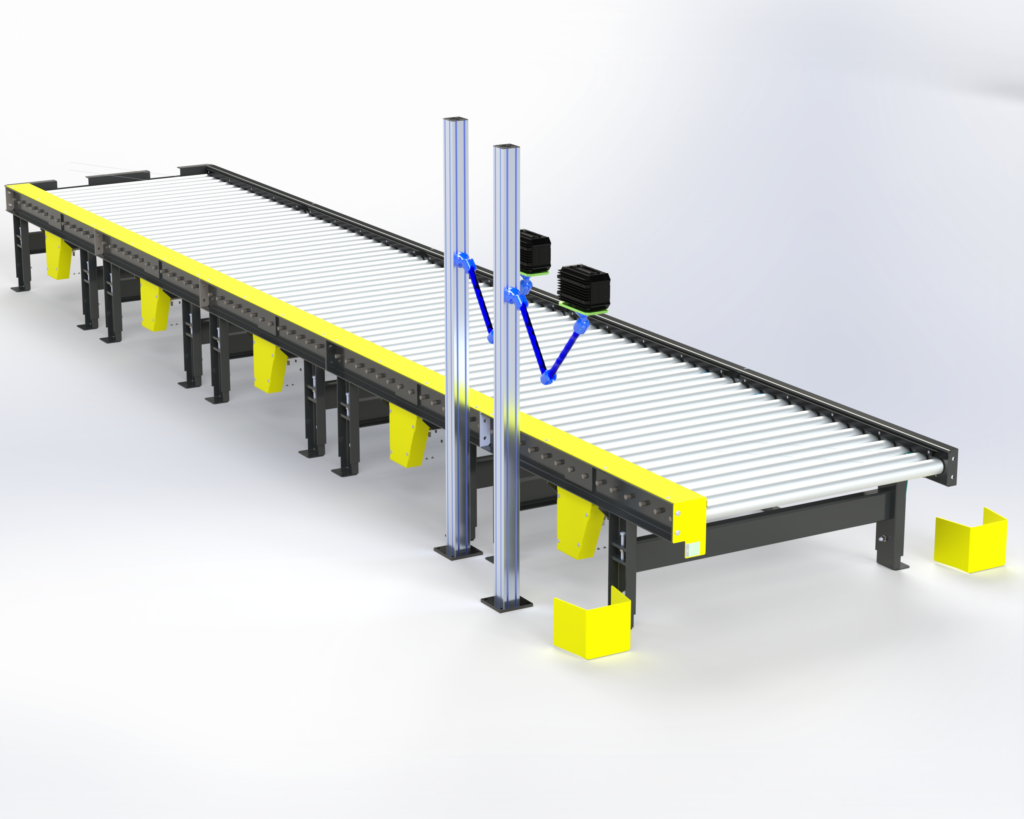

AutoLink 1500 PD1

The AutoLink 1500 CDLR (Chain Driven Live Roller) Module is a top-of-the-line, automated material handling system designed by Autotec Solutions specifically for integration with the OTTO 1500 autonomous mobile robot (AMR).

AMR Powered Conveyor

The AutoLink 1500 Pickup & Drop-off Conveyor Stand, developed by Autotec Solutions, is a non-powered conveyor engineered for direct integration with autonomous mobile robots (AMRs) equipped with the AutoLink PTO. This system is designed without wiring to facilitate ease of installation and maintenance in industrial applications, ensuring compatibility with AMR systems for streamlined logistics and material handling processes.

ideal use cases

Warehouse Operations

Streamline the movement and storage of various goods with safe and efficient pallet handling.Manufacturing Facilities

Facilitate the seamless transfer of materials between different stages of production.Distribution Centers

Enhance loading and unloading efficiency, crucial for timely distribution operations.Large-Scale Retailers

Operates without needing the count of boxes per pallet layer, adding to its intuitive design.

additional AutoMove Series Conveyors

AutoMove with AutoLink PTO

The AutoLink 1500 CDLR (Chain Driven Live Roller) Module is a top-of-the-line, automated material handling system designed by Autotec Solutions specifically for integration with the OTTO 1500 autonomous mobile robot (AMR).

AMR Powered Conveyor

The AutoMove 1500 Top Module, crafted by Autotec Solutions, is an automated material handling system that seamlessly integrates with the OTTO 1500 autonomous mobile robot (AMR). It enhances its functionality with the optional AutoLink PTO, enabling efficient powered transfers to non-powered passive conveyors like the AutoLink 1500 Pickup & Drop-off Conveyor Stand. Additionally, this versatile top module possesses the capability to interact with conventional powered conveyors.

AutoLink 1500 PD1

The AutoLink 1500 CDLR (Chain Driven Live Roller) Module is a top-of-the-line, automated material handling system designed by Autotec Solutions specifically for integration with the OTTO 1500 autonomous mobile robot (AMR).

AMR Powered Conveyor

The AutoLink 1500 Pickup & Drop-off Conveyor Stand, developed by Autotec Solutions, is a non-powered conveyor engineered for direct integration with autonomous mobile robots (AMRs) equipped with the AutoLink PTO. This system is designed without wiring to facilitate ease of installation and maintenance in industrial applications, ensuring compatibility with AMR systems for streamlined logistics and material handling processes.

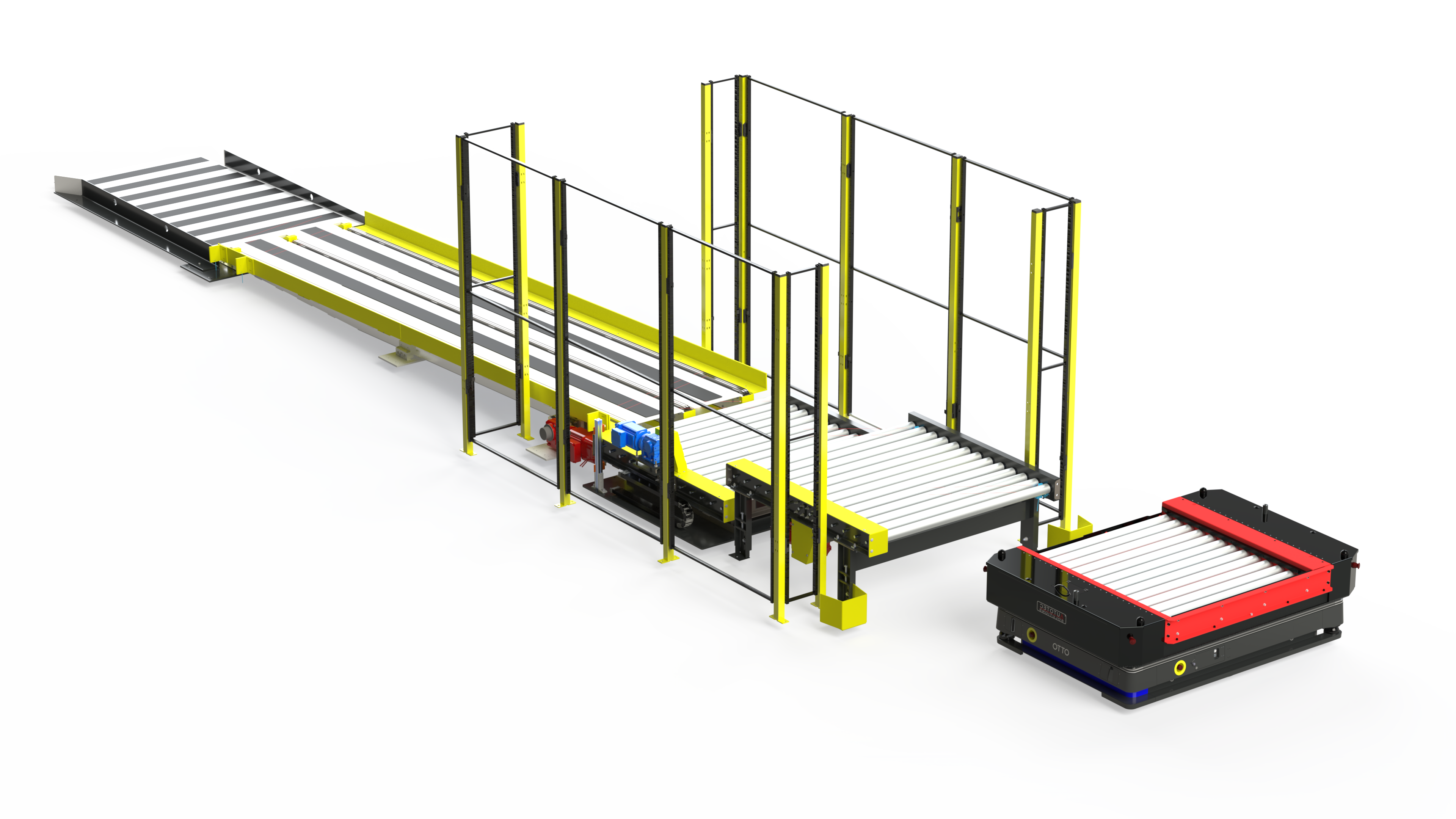

On The Fly System Integrations

Numerous integration options exist for incorporating the random case palletizer into various warehousing and manufacturing systems. We’ve established several standard system integrations, including rotary arm stretch wrappers, conveyors that interface with Autonomous Mobile Robots (AMR), and robots mounted on rails.

Rotary Arm Stretch Wrapper

The Rotary Arm Stretch Wrapper is an automated system with an infeed, wrapper zone, and outfeed conveyor. It wraps stationary loads with a 20-inch film, featuring a 200% standard pre-stretch for 60 to 100 gauge films. Safety is ensured with fencing and a light curtain, capable of wrapping loads up to 87 inches high. The machine offers adjustable wrap patterns through the HMI and includes a pop-up feature for thorough wrapping.

FLEET MANAGEMENT EXPERIENCE

Automate material handling at enterprise-scale with the world’s most powerful Autonomous Mobile Robot (AMR) fleet management software.

As a system integrator, Autotec Solutions has expertise in deploying OTTO Fleet Manager software for various clients. Our experience ensures seamless integration with existing infrastructure, providing a symbiotic enhancement to efficiency and intelligence in automated material transport systems.

Robots On Rails

The optional Robotic Transfer Unit elevates productivity to new levels. This state-of-the-art addition, functioning as a robot on rails, incorporates robot-mounted vision technology. It effectively increases the number of pick and build locations, thereby enhancing overall operational efficiency. By capitalizing on this feature, businesses can significantly maximize their spatial utilization and throughput, making it a worthy investment for high-volume operations.