Automatic Roll Handling Systems

Autotec Solutions: Roll Handling Experts

At Autotec, we specialize in handling and packaging products that come in roll form, such as flexible films, nonwovens, paper, linerboard, towel, and tissue. We understand that each type of product has its own unique properties, and we know that Roll Handling requires a different approach than other material handling methods.

Our experienced team is dedicated to ensuring the success of your project. From the unwind process all the way through converting, our heavy-duty designs provide reliable systems for demanding manufacturing environments.

At Autotec, we take pride in fully understanding our customers' requirements, providing exceptional customer service, and completing projects to 100% satisfaction. This sets us apart and keeps our customers returning for their next Roll Handling project.

If you're ready for a new journey on your next Roll Handling project, trust Autotec to get the job done right. It's in our DNA to earn your trust and keep it.

Engineering Excellence

Autotec Solutions ensures that every system is meticulously prepared with a team of experienced controls engineers and proven project managers so that you can count on Autotec Solutions to take your project to the finish line.

Diverse Industry Applications:

Autotec Solutions is adept at tackling a variety of material handling needs, ensuring seamless operation across different industrial landscapes.

Custom Roll Handling System Solutions

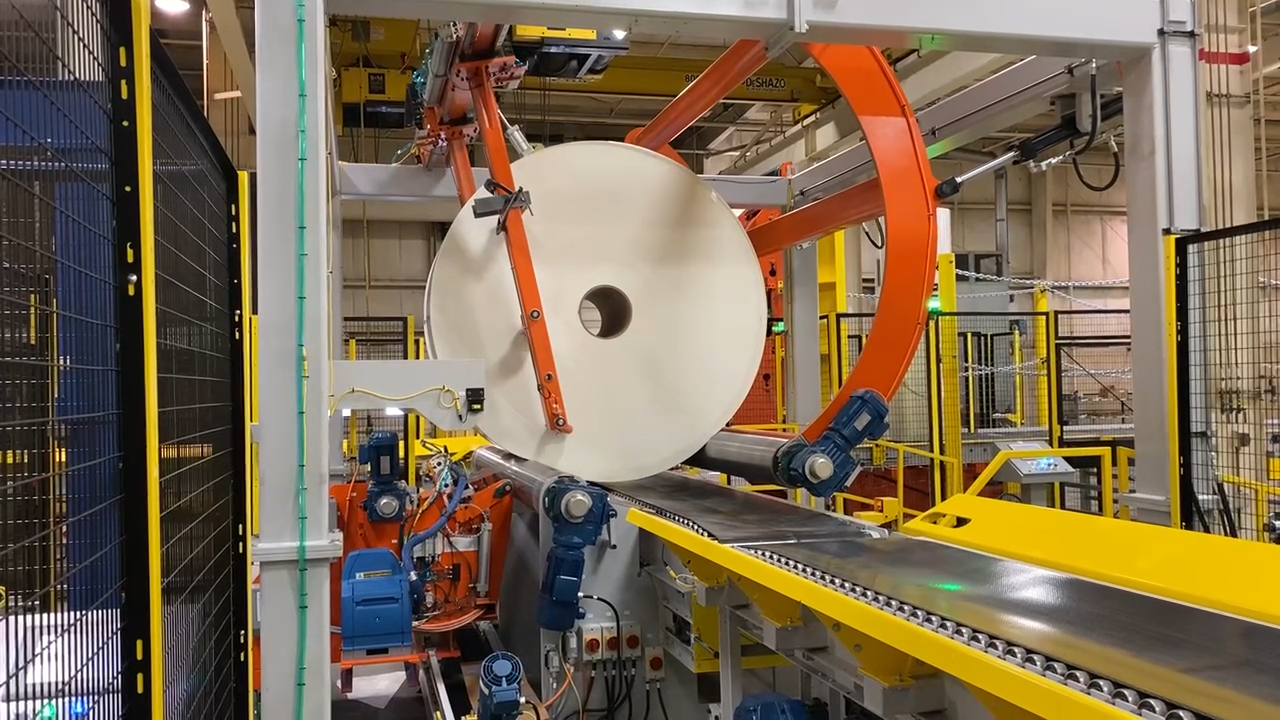

Parent Roll Handling

Streamline your workflow and protect your valuable materials with our Parent Roll Handling systems, designed for safe and efficient maneuvering of large rolls.

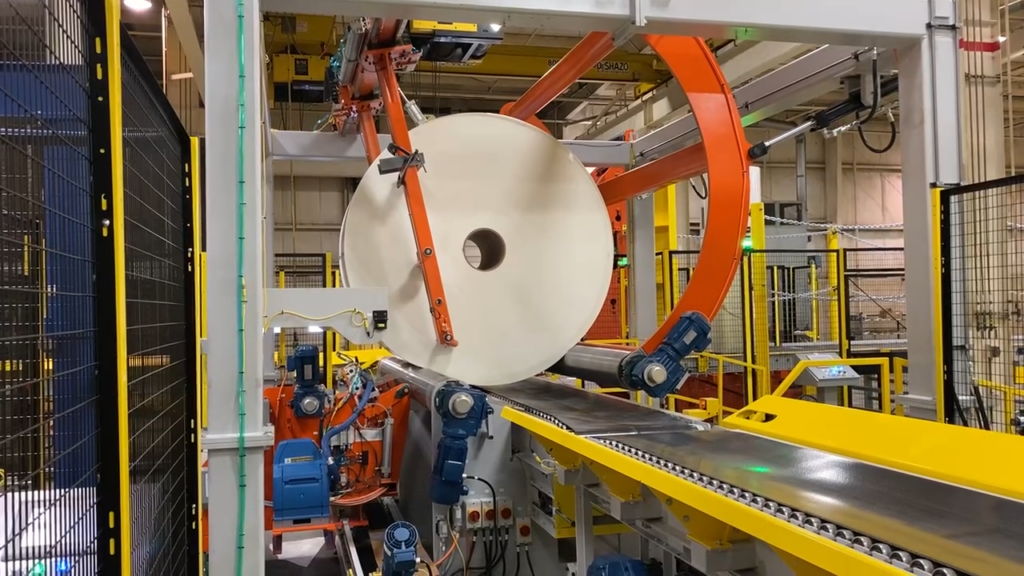

Upending and Downending Equipment

Our Upenders offer a secure and effortless way to reposition rolls, improving operational adaptability while minimizing handling hazards. Their compact design and low energy consumption make them an outstanding solution.

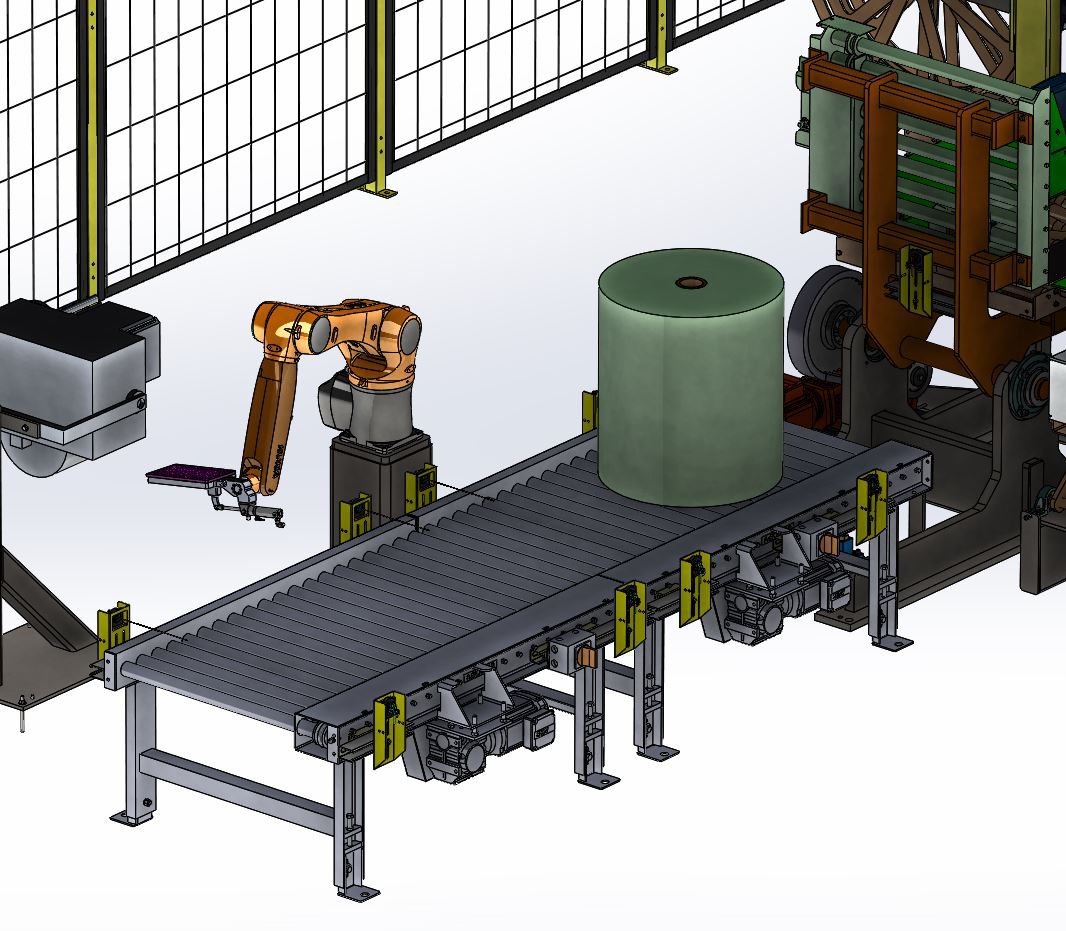

Robotic Labeling

Our Robotic Labeling solutions provide precise and consistent labeling, whether on core IDs or roll ODs. These enhance product presentation and traceability while requiring minimal human input.

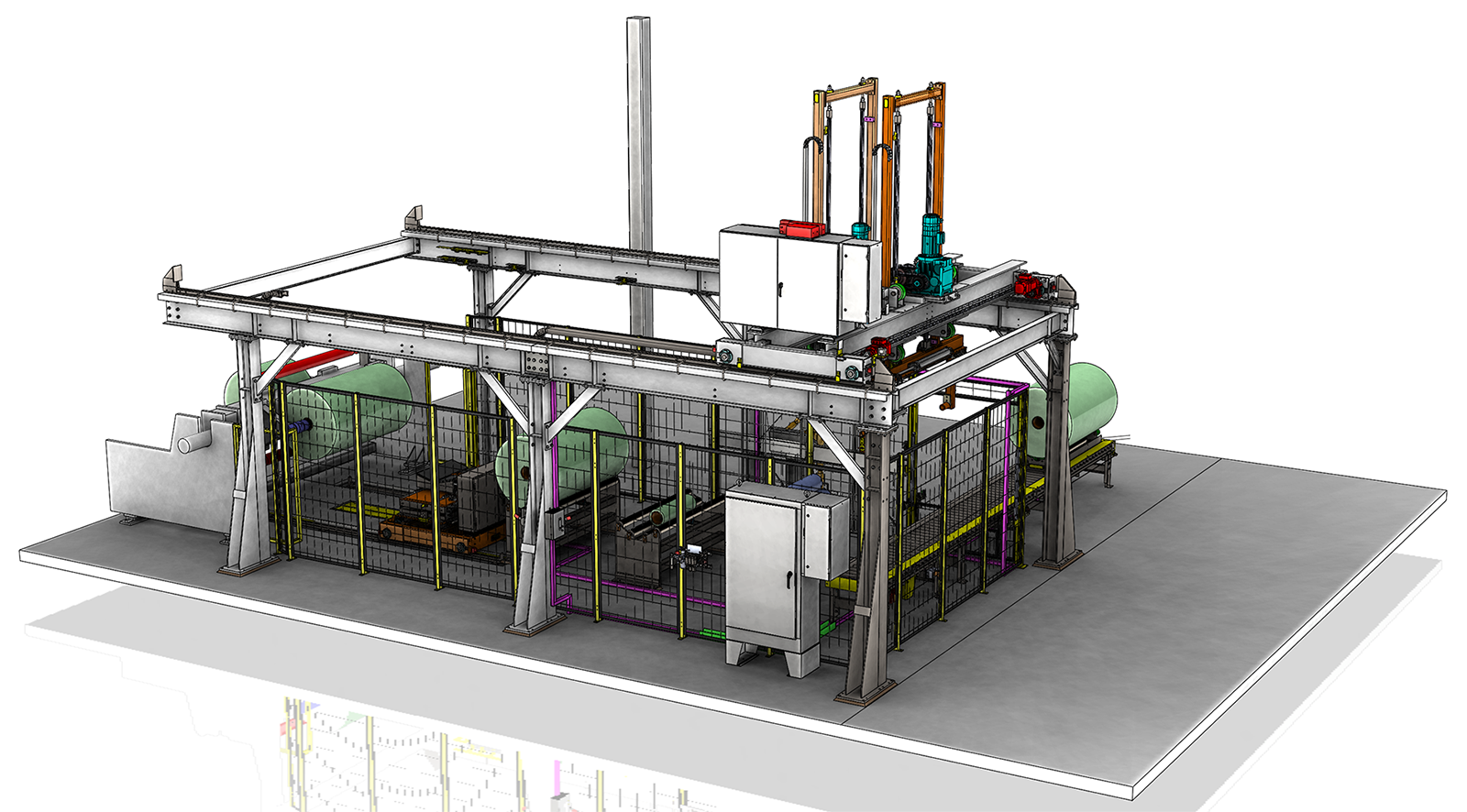

Winder Loading & Unloading

Maximize productivity and minimize downtime with our automated Winder Loading & Unloading solutions, making the process faster and more reliable.

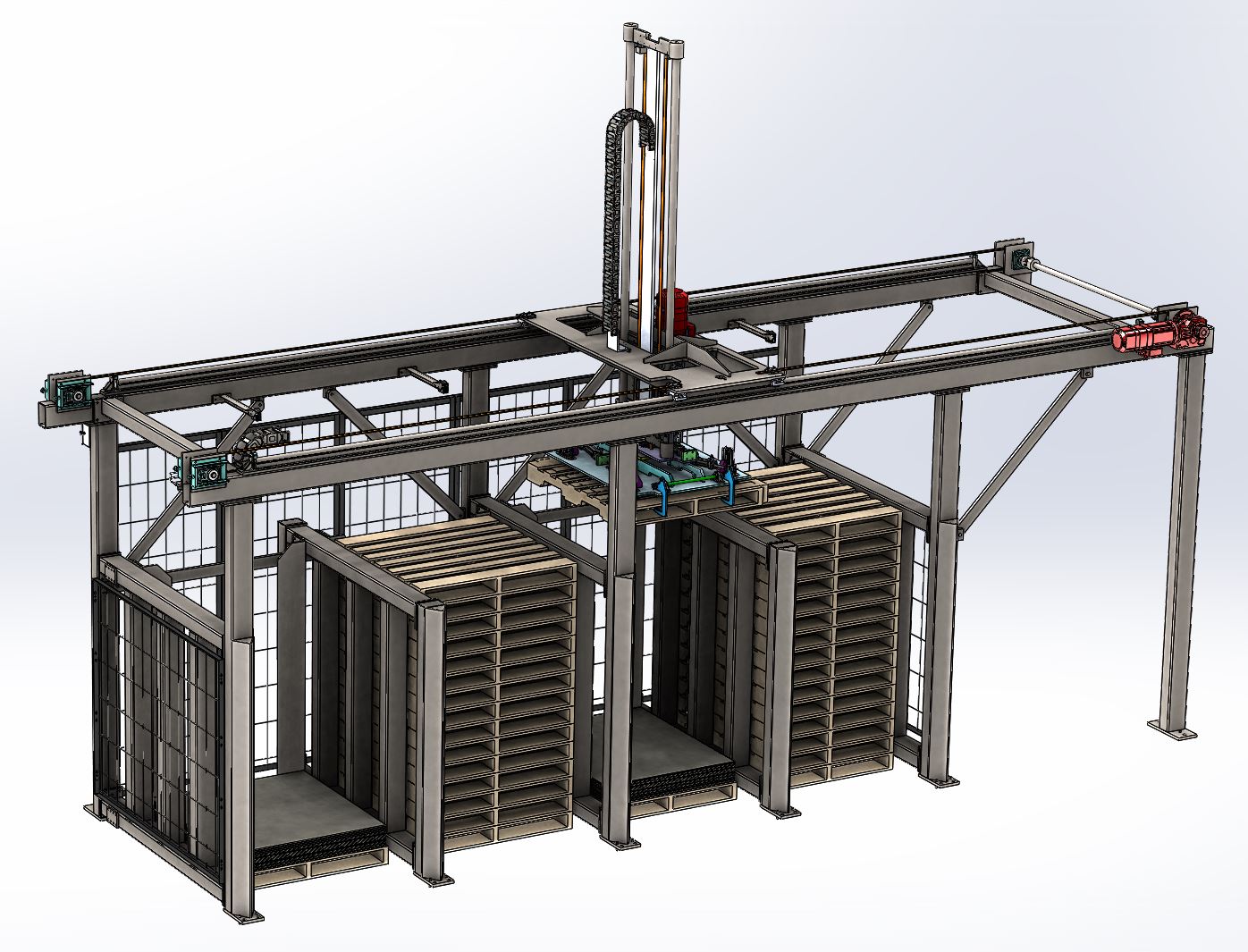

Automatic Core Handling & Feeding Systems

Enhance productivity and decrease labor requirements with our Automatic Core Handling & Feeding Systems, which simplify the core preparation process and optimize the management of consumables and waste.

Custom Robotic Integration

From Robotic Header Placement to integrated solutions, our systems ensure seamless operations and enhanced efficiency across the board.

Roll Wrapping Systems

Keep your products secure and damage free with our Roll Wrapping Systems, providing consistent wrapping quality while reducing material waste.

Overhead Cranes & Hoists

Lift and move heavy rolls effortlessly with our Overhead Cranes & Hoists, designed for safety and reliability under substantial loads.

Roll Inspection Stations

Elevate your quality assurance with our Roll Inspection Stations, designed for comprehensive and automated checks including weight, dimensions, RFID scanning, sorting, and counting, ensuring your products adhere to the strictest quality standards.

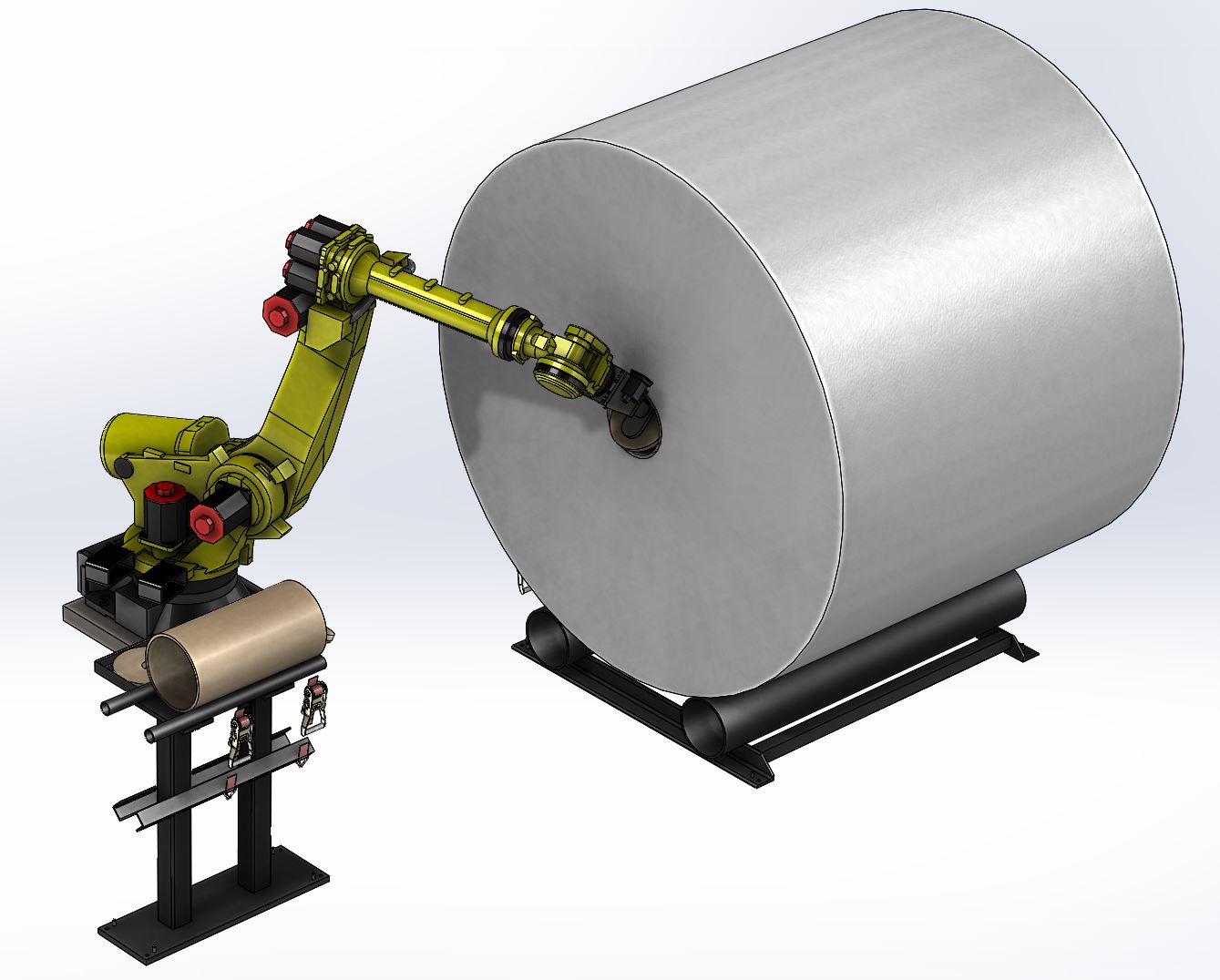

Damage Free Robotic Roll Plugging

Eliminate safety issues from manual operations, and prevent core damage with our precision-engineered Robotic Roll Plugging, ensuring the integrity of your rolls throughout processing and transport.

Heavy-Duty Roll Transfer Carts

Optimize intra-facility transport with our Heavy-Duty Roll Transfer Carts, built to move large rolls effortlessly and safely across the plant floor.

Custom AGV & AMR Solutions

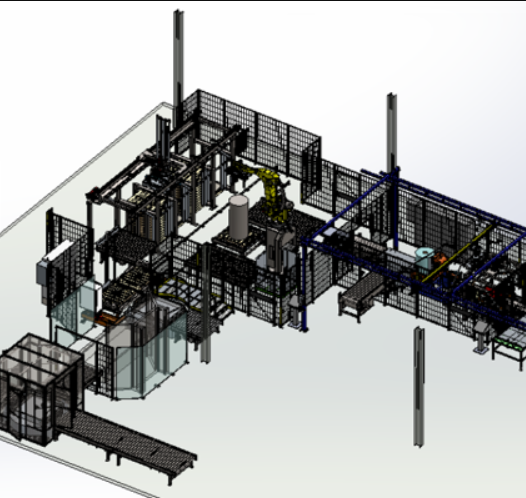

Revolutionize your material handling with our Custom AGV & AMR Solutions, tailored to enhance efficiency and safety across your facility. From fleet roll loading solutions and consumable management to individual waste stream automations, our systems are designed to optimize transportation processes.Complete System Integration: Turnkey Solutions

Complete Setup & Testing:

Ensure seamless operation and optimal performance with our comprehensive setup and testing services:

Advanced Automation Engineering

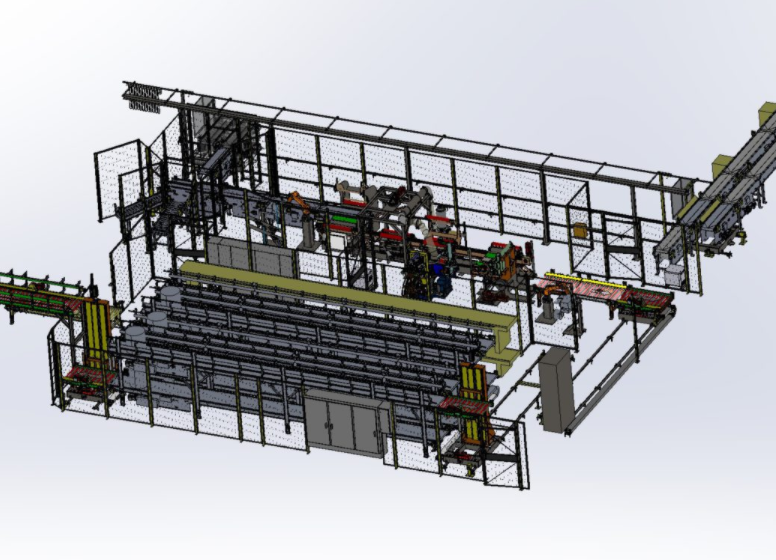

Parent Roll Unload to End of Line Packaging

WInder Unload Roll Handling Systems

Decades of industrial design experience have honed Autotec Solutions' engineering approach to designing specialized equipment, including shaft extractors, winder unload tables, and robotic core pluggers. Our design process is systematic and client-focused, reflecting our dedication to delivering functional, efficient, and tailored solutions.

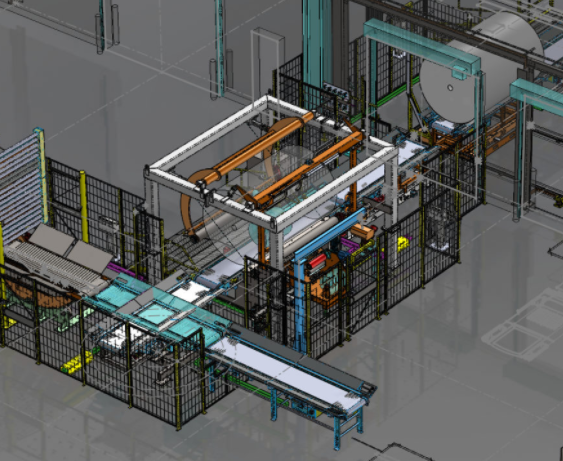

Automatic Overhead Gantry Systems

Automatic overhead gantry systems are designed to facilitate the smooth and automated transfer of materials from the winder to the unload table. These systems are particularly beneficial in high-volume production environments where speed, precision, and minimal human intervention are paramount. In designing these systems, we focus on:

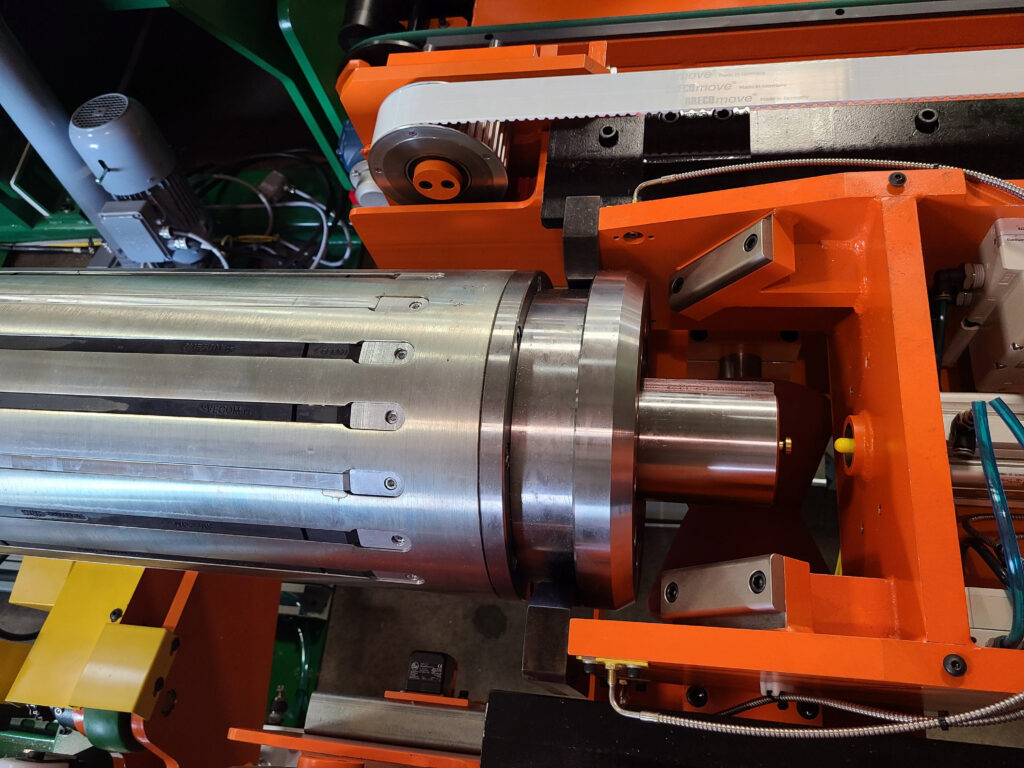

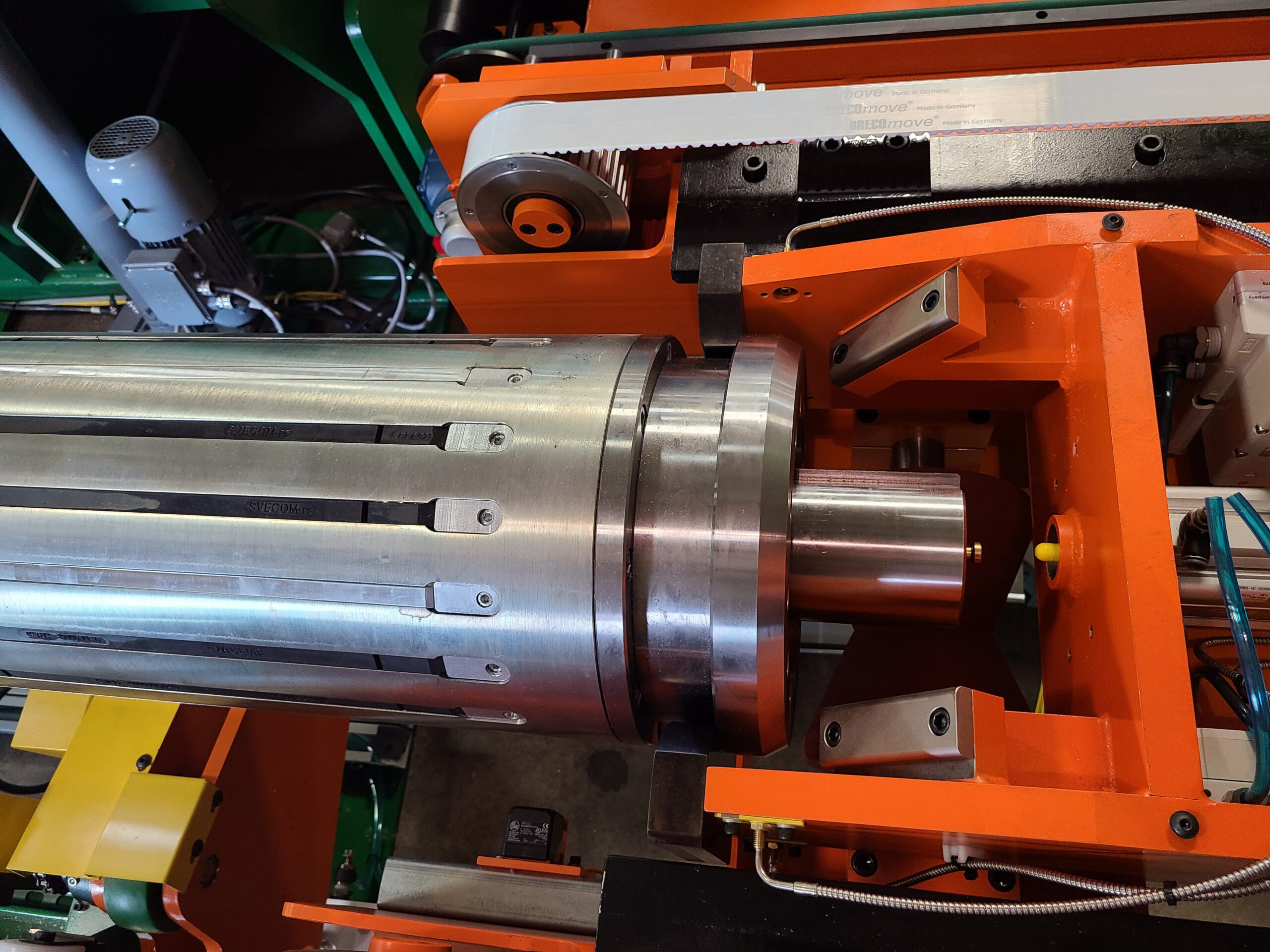

Shaft Extraction & Automatic Core Feeding Systems

When designing a shaft extractor, our engineers first conduct an analysis of the load characteristics and the operating environment. We consider factors like the weight of the rolls, the size of the shafts, and the frequency of extraction operations. Ergonomics play a crucial role in our design philosophy to ensure operator safety and ease of use.

Winder Unload Tables

The design of a winder unload table requires a deep dive into the specifics of the material handling process. We look at the nature of the material being wound, the space constraints of the facility, and the required speed of the processing line.

Damage Free Roll Pluggers

Robotic core pluggers are designed to place core plugs with accuracy, ensuring the cores are perfectly aligned for the winding process. This consistency enables uniform product quality and reduces material waste. By automating the core plugging process, human intervention is minimized, reducing labor costs and enhancing safety.

Roll Handling Equipment

Autotec has a complete portfolio of roll handling equipment, from winder unload of parent rolls to autonomous mobile robot moving palletized

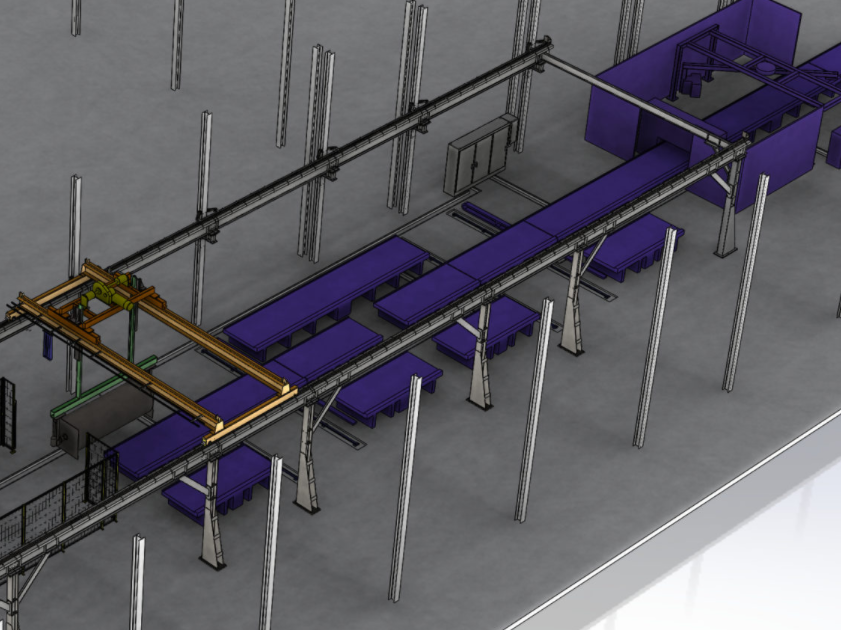

Transfer Carts

Transfer carts offer a mobile solution for safely moving large and heavy rolls from one point in a facility to another. Autotec transfer carts can utilize either in-floor rail systems for unobstructed floor space and a guided pathway, or above-ground rails that are easier to install and can be integrated into existing floor layouts.

Roll Kickers & Cushions

Autotec Solutions employs a variety of roll kickers and cushions within their roll conveyance systems to ensure smooth and precise handling of materials. The kickers, integrated seamlessly into the conveyor line, utilize pneumatic, hydraulic or electric actuation to swiftly and accurately reposition rolls.

Custom Roll Conveyance

At Autotec Solutions, we leverage our wealth of knowledge and customer focus to create machinery that meets the specific needs of our clients. From custom turntables to c-hook conveyors, we can engineer equipment that solves current challenges and adapts to future demands.

Roll Upending and Downending

Roll upenders and downenders serve as essential tools for efficiently reorienting rolls from horizontal to vertical positions, and vice versa. This reorientation plays a pivotal role in processes like storage, shipping, or seamlessly integrating rolls into production lines. Featuring a compact design, our heavy-duty upenders are engineered to be fully customizable, ensuring they perfectly adapt to any space requirement.

Gantry & Overhead Roll Handling Solutions

Overhead, or bridge crane, roll handling systems are installed on fixed structures above the workspace, such as along the ceiling or on high steel beams. These systems consist of a horizontal bridge or beam that spans the work area, with a moving hoist or trolley that carries loads across this bridge. Overhead roll handling solutions provide a permanent, stable platform for moving heavy rolls, optimizing floor space by utilizing the upper area of a facility.

Custom AMR & AGV Solutions

Overhead, or bridge crane, roll handling systems are installed on fixed structures above the workspace, such as along the ceiling or on high steel beams. These systems consist of a horizontal bridge or beam that spans the work area, with a moving hoist or trolley that carries loads across this bridge. Overhead roll handling solutions provide a permanent, stable platform for moving heavy rolls, optimizing floor space by utilizing the upper area of a facility.

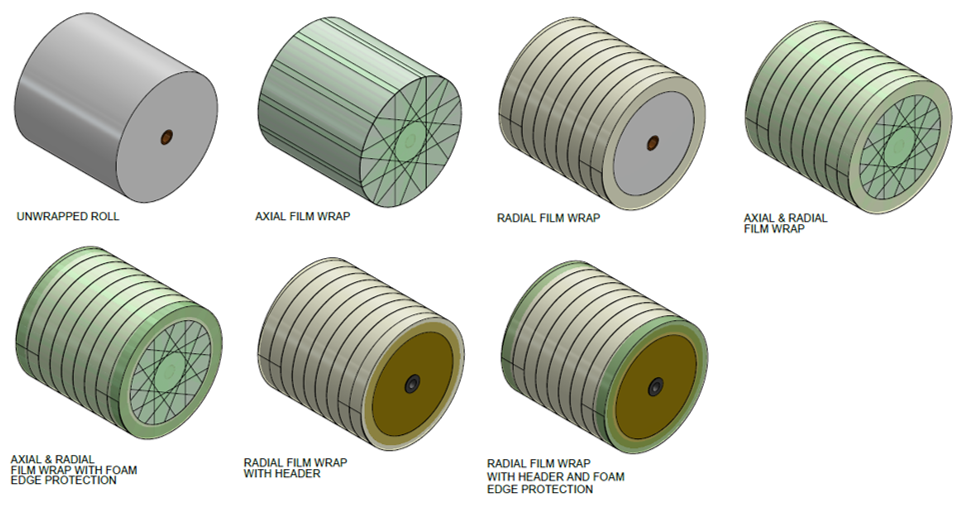

Roll Wrapping Systems

Autotec's roll wrapping systems are engineered for optimal protection and handling efficiency. With a strong emphasis on custom solutions, Autotec integrates robotic header placement and top sheet integration into wrapping processes, offering unparalleled customization, durability, and ease of operation.

Horizontal Roll Wraplines

Our horizontal highspeed roll wraplines accommodate large and small-scale applications, seamlessly integrating into production workflows for superior wrap integrity, edge protection, and throughput.

Vertical Roll Wrapping Systems

Our vertical arm stretch wrappers deliver precision and speed, wrapping rolls tightly to maintain stability and reduce material waste.

Configurable Package Design

Whether it’s securing delicate items with our precision-engineered foam options or utilizing our robust film wraps for moisture and dust resistance, our products are tailored to enhance the safety and integrity of your goods during storage and transit.

Robotic Header Placement & Integration

Our robotic header placement systems feature adjustable alignment capabilities, which ensure consistent application and optimal roll protection. They easily accommodate a variety of roll sizes and header types.

Integrated Robotic Labeling

Our technology portfolio includes core ID labeling and roll OD labeling, ensuring accurate placement and consistent quality for better traceability and inventory management. We also offer customizable robotic labeling solutions tailored to specific operational needs, enhancing both efficiency and product presentation.

Start Your Automation Journey

The Autotec Process

Autotec Roll Handling Systems

Autotec Capabilities

Roll Handling & Robotics

- Parent Roll Handling

- Converting - Slitter Load / Unload

- Overhead Cranes

- Shaft Handling

- Core Handling

- Belt Conveyors

- Slat Conveyors

- Axial Roll Wrapping

- Radial Roll Wrapping

- Vertical Roll Wrapping

- Upender

- Roll Kicker

- Palletizer

- Pick & Place

- I.D and O.D Labeling

- Pallet Labeling

- Header Placement

- Lowerator

- Core Plug Placement

- Transfer Carts

- Pallet Handling

- Accumulation Conveyors

Integrations & Services

- Project Management

- Electrical & Mechanical Engineering

- Controls

- IT Interface

- Panels

- Wiring

- Installation

- Supervision

- Start-Up

- Spare Parts

- Remote Service Ptimization

Ready to connect?

Contact Us TodayOur sales teams are ready to answer any questions you may have and get your project started.